-40%

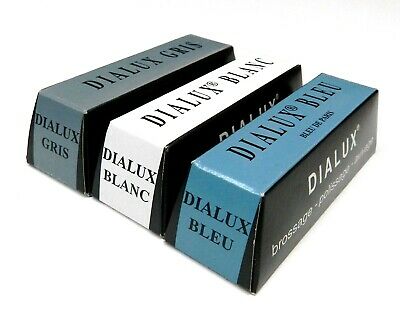

Polishing Compound for Knives Metal Finishing Cut & Polish Buffing Compounds 3pc

$ 10.5

- Description

- Size Guide

Description

POLISHING COMPOUNDSD

I

A

L

U

X

®

Brand

METAL POLISHING COMPOUNDS

CUT - POLISH - SHINE

SET OF 3 FOR KNIFE BLADE

FINISHING

-

HIGH SHINE ON ALL METALS

JETS PRODUCT # 1614-90304050

D

i

a

l

u

x

®

Brand

polishing compounds originally formulated in France has been a popular polishing compound for over 50 years

.

The Dialux

®

polishing compounds are a high grade

PREMIUM

polishing line of compounds specifically formulated for Precious Metals in Jewelry Polishing.

We use the terminology "Rouge" (French meaning for Rouge is Red) as it has become the popular word used to describe many of the Jewelry Polishing compounds.

The

Dialux

®

Brand of compounds are popular worldwide and are widely used by Jewelers, Silversmiths, Watchmakers, Creative Arts Metalworking, by Metalsmiths and in Automotive Detailing.

- GRIS - GRAY

JETS

#1614-940

- Dialux

®

Gris - Gray

is a premium polishing compound formulated especially for white color hard metals, like Stainless Steel, White Gold, Platinum, Chrome Alloy and works with Sterling Silver.

Use a small amount of this compound on a Muslin Buff.

Gris is

has a medium grade composition, with uniform abrasion, good cutting for hard metals is used as a cutting compound, it is a premium grade Tripoli, cuts and brings out the metal color, a semi-polish that refreshes the metal.

- BLANC -

WHITE

JETS

#1614-930

- Dialux

®

BLANC-

WHITE

Polishing compounds a premium compound for white metals.

Dialux White is formulated especially for Silversmiths and Goldsmiths to polish

White Gold,

SILVER

.

The Dialux White is widely used by Metalsmith’s for a High Polish Finish. Use a small amount of this compound on a Muslin - Finex - White Buff, make sure buff edge is clean for best results.

-

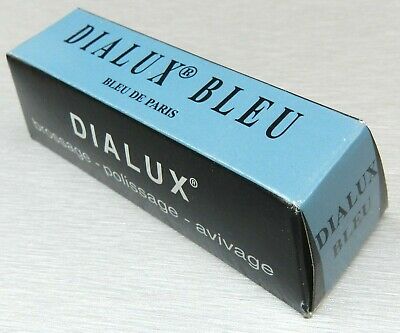

BLEU DE PARIS - BLUE

JETS

#1614-950

-Dialux

®

Blue

is an all around premium polishing compound formulated to give a very

High Luster Shine.

Dilalux Blue can be used on all metals, precious metals and chrome alloys to produce a

Final High Shine Finish

. The Blue compound is used as a last step on all metals to provide that extra Gleam. Use with a White Finex Muslin Buff or with a Chamois Buffing Wheel, make sure the buff is clean, use a Buff rake to remove and clean buff. The Dialux Blue polish is widely used by Jewelers, Silversmiths, Auto Wheel Detailing, and Metal-smiths.

NOTE:

We have included polishing recommendations at the bottom of this page, to assist you.

COMPOUNDS:

Bar size:

4" x 1" x 1-1/8" - 100mm x 25mm x 30mm

Bar Weight:

120 Grams - 4 Oz.

Bars are individually wrapped

·

Utilize Graded Abrasives

·

Blended with Additives

·

Long Lasting Composition with Minimum Usage

·

Good Adhesion to Buffing Wheels

·

Produces - Best Finish to High Luster

Made by Lippert/Unipol

SALE is for 3 BARS

BLUE

WHITE

GRAY

Items are Brand New in original sealed Packages.

SHIPPING: Via First-Class Mail® Package

NOTE: Visit

JETSTOOLS

our

ebay

Store Listings, where you can see the variety of

D

i

a

l

u

x

®

Jewelry Polishing Compounds, Buffing Wheels and more

J

ewelers

E

quipments

T

ools

&

S

upplies

.

JETS Inc.

POLISHING RECOMMENDATIONS:

Our recommendations and suggestions on Buffing to obtain the best results possible:

·

Use the right compound for the metal that you are trying to polish

·

It may be needed to go through 2 or 3 steps, in polishing to get the optimum result you are looking to achieve

.

·

Make sure that the parts that are being polished are smooth and clean, use the

appropriate abrasive to remove lines and scratches

.

·

Avoid using different compounds

with the same buff, if you have to then make sure to clean and remove any hardened compound residue on the surface edge with a buff

rake

.

·

Segregate your buffs for the various metals, Gold, Silver, Brass … try not to use the same buff for all metals.

If you have to then make sure buffs are cleaned

(

dressed) with a buff rake

.

·

A clean buffing wheel edge is important

.

·

Allow the buff and compound to perform the work they were made and formulated for, excessive force or pressure will hurt the process

.

·

Whenever you are working with Platinum never use a buff that was used for another type of

metal

.

WORK

SAFE!

Working with rotary motors and wheels can be dangerous, if proper safety procedures are not followed.

Protect yourself, your fingers and hands, your face and eyes, and use respirators

.

13E 2X-1.7 FRENV 3X-2.4 FRENV 113 CKSP

.

Z M P